A few years ago, as a complete novice in the field, I used to think that all types of printing were similar: newspapers, brochures, invitation cards, cereal boxes, magazines, movie posters… However, there are numerous printing techniques, ranging from pocket-sized printers to machines as large as an airplane. Printing has been around for about 2000 years, leading to various experiments and ingenious methods. In this article, we will explore offset printing, one of the most versatile printing techniques.

What is Offset Printing?

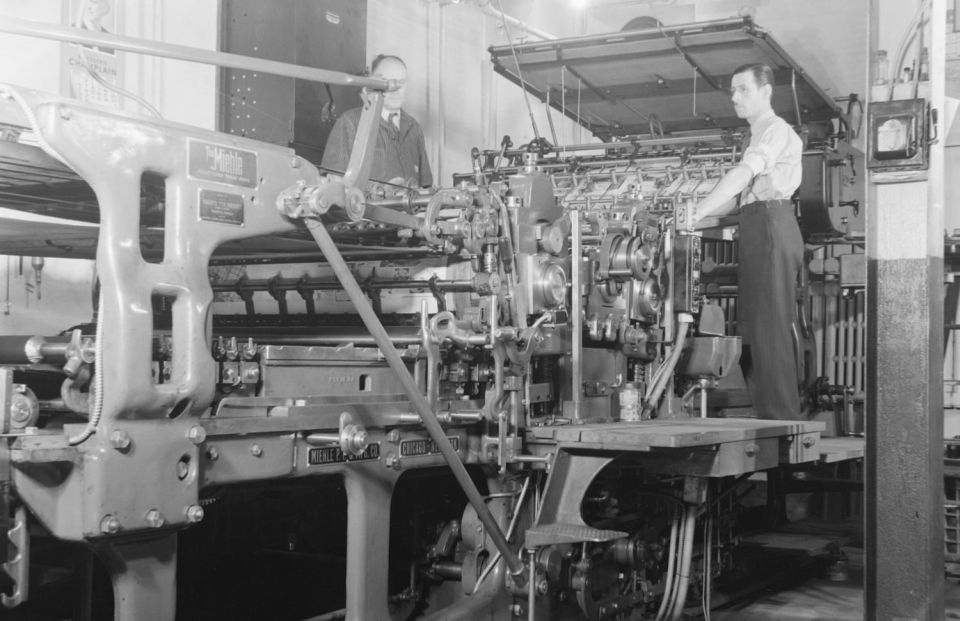

Offset printing is a highly versatile printing method that utilizes offset presses, machines measuring between 2 and 40 meters in length. These presses work with paper in the form of sheets or rolls, which are then automatically cut and printed.

The Principle of Offset Printing: A Method for High-Quality Printing

The principle of offset printing lies at the heart of this technique. It involves transferring ink from a plate to a rubber blanket, which then applies the ink to the paper. The offset process allows for consistent and precise printing, resulting in high-quality output. Here's a more detailed explanation of how offset printing works.

Origins of Offset Printing

Offset printing has its roots in the late 19th century, when it was developed as an alternative to the traditional letterpress printing method. It gained popularity due to its ability to produce sharper and more consistent prints. Offset printing has since evolved and become one of the most widely used printing methods worldwide.

Miehle offset press for printing the newspaper on Saturday. Montreal, March 3, 1939.

Advantages and Limitations of Offset Printing

Offset printing offers several advantages, including:

- Excellent image quality and sharpness

- Consistent and accurate colour reproduction

- Versatility in handling various paper types and sizes

- Efficiency for large print runs

However, offset printing also has some limitations:

- Setup costs can be relatively high, making it less cost-effective for small print quantities.

- Frequent colour changes can extend the setup time and increase costs.

- Offset printing may not be suitable for specialized printing effects, such as metallic inks or embossing, which require alternative printing methods.

Applications of Offset Printing

Offset printing is widely used for various printed materials, including:

- Books and magazines

- Brochures and catalogues

- Posters and flyers

- Business stationery

- Packaging materials

The offset printing process involves several steps:

- Preparation of the printing plates, usually made of aluminum, with the desired image or text.

- Ink application to the plates, with the non-printing areas coated with a water-repellent substance.

- Transfer of ink from the plates to the rubber blankets.

- Final transfer of ink from the blankets to the paper.

Conclusion

Offset printing is a versatile and widely adopted printing method known for its high-quality results. Its ability to handle different paper sizes and produce sharp prints makes it suitable for a wide range of applications. While setup costs may be a consideration, offset printing excels in large print runs and projects that require consistent and precise colour reproduction.